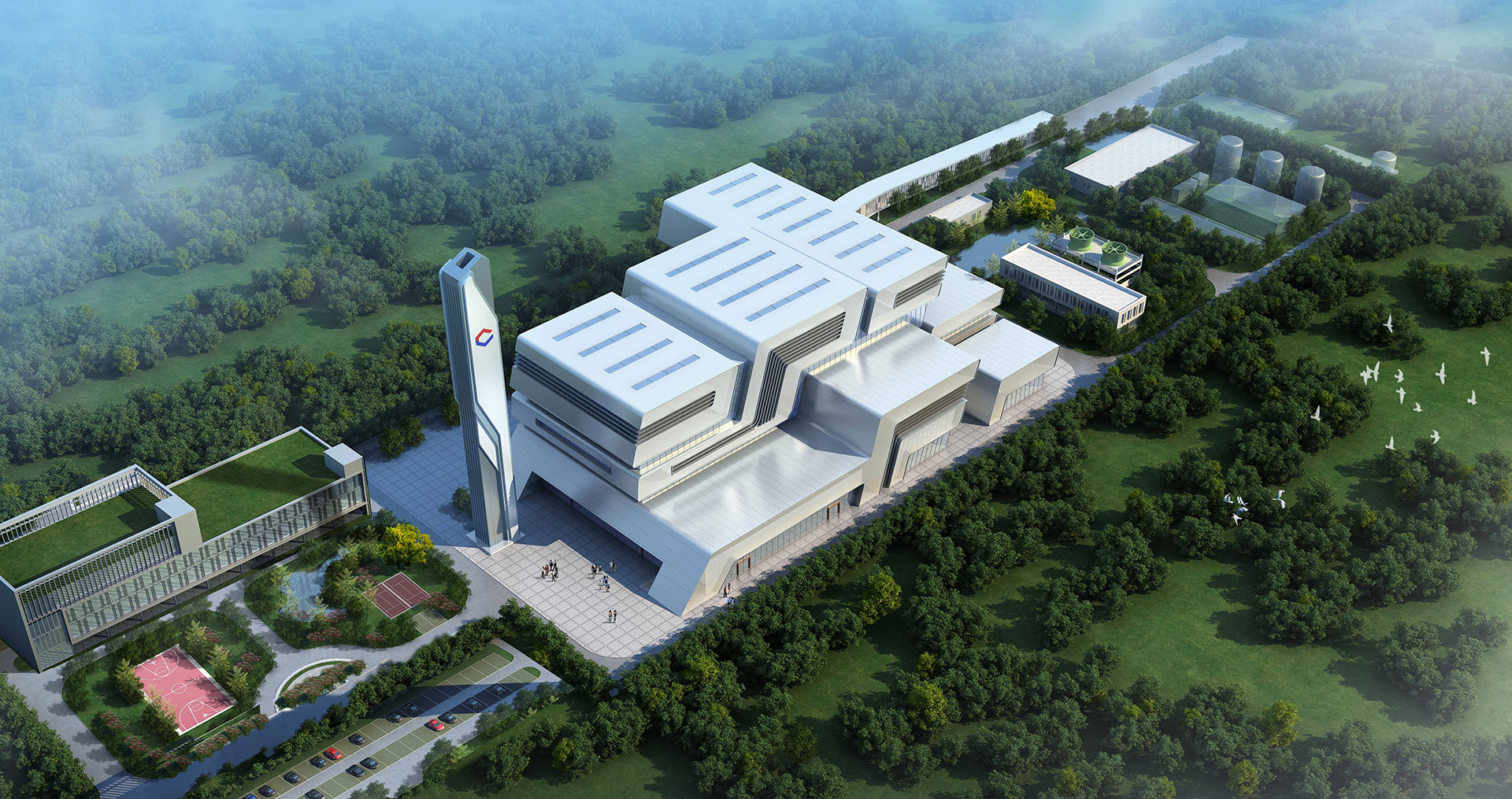

WTE Project in Dengzhou City

With the rapid social and economic development of China, the continuous improvement of people's living standard and the acceleration of urbanization, a large amount of domestic waste, kitchen waste, construction waste and various disused materials began to occupy a large amount of land, threatening the ecological environment. According to market statistics, the downtown of Dengzhou city generated about 400t/d waste in 2016. The volume of waste in surrounding villages and towns is greater than that in downtown city, and the total volume will continue to grow. Municipal solid waste is currently all disposed of in centralized landfills, but it hardly reduces the amount of waste. In addition, the landfill in Dengzhou is almost full. Meanwhile, landfill takes up a lot of land while incineration can reduce waste volume by 90% and thus greatly saves the land.

Eco-efficient parks encourage a centralized and recycling treatment of low-value garbage, such as domestic waste, construction waste, kitchen waste and garden waste. It transforms the traditional linear model of "resource-product-waste" into a circular economic model of "resource-product-renewable resource", turning waste into treasure.

The plant is located 0.6 km to the south of Guodanying Village, Taoying Town, Dengzhou City, and 1km to the west of West Chenzhuang Village. The project adopts PPP mode. The daily processing capacity is 1,500 tons but divided into two phases. The first phase is 1,000 t/d, using 2×500 t/d incineration lines; and the rest 500 t/d in the second phase. The equipment will run no less than 8000 hours. The main buildings will be completed at one time, and land for second-phase construction will be reserved. The plant will also be equipped with a leachate treatment factory, the processing capacity of which is 350 t/d.

The completion and operation of this project will play a positive role in alleviating the power supply shortage in Dengzhou city and will also help to improve the energy mix.

Other main features are listed below:

1. The design low calorific value of the domestic waste in this project is 6500kJ/kg (1550kcal/kg), and the design range of lower calorific value is 4180~8360kJ/kg (1000~2000kcal/kg).

2. The incineration process of this project adopts the advanced and mature mechanical grate furnace. In the first phase, two incinerators will be installed, with the daily processing capacity of each one is 500 tons. The type of steam boiler is medium temperature and medium pressure (400℃, 4MPa), equipped with a set of 20MW condensing steam turbine generator set, and the steam condensing method is water cooling.

3. The flue gas purification system of this project adopts the process of SNCR + semi-dry method (Ca(OH)2 solution) + dry method (NaHCO3 dry powder) + activated carbon adsorption + bag dust removal", and its flue gas emission index falls within the requirement in National Control Standard on Household Garbage Incineration Pollutant (GB18485-2014).

4. The slag produced in this project will be recycled to make bricks; the fly ash is solidified and then transported to the waste landfill while enough space has been reserved.

5. The leachate and domestic sewage in this project are sent to the leachate treatment station for centralized treatment. The capacity of the treatment station for the first phase is 350 cubic meters/d, and 500 cubic meters/d for the second phase. The land for the second phase has been reserved.

6. The capacity of the steam turbine generator in the first phase is 20MW. The annual power generation under MCR working condition is about 1.304×108kWh, and the annual on-grid power is about 1.043×108kWh/a. The electricity generated by this project can be finished within Dengzhou City. In the second phase, a set of 10MW steam turbine generator sets will be added.